Sioux Water Pressure Washers

Sioux Water Pressure Cleaners

Different Machines for different Applications… What Type of Cleaner is Best for You?

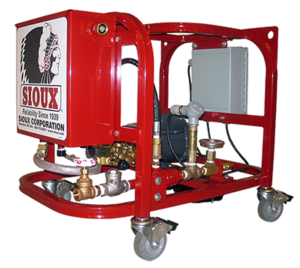

Cold Pressure Washers

Sioux cold pressure washers are excellent for lighter cleaning jobs such as washing off dirt, dust and mud, and maintaining vehicles and grounds. Cold pressure washers are easy units to operate, since water is not heated, therefore there are fewer components, and less maintenance, The initial cost and operating expense of cold pressure washers is less than most other cleaning methods. Units come complete with pressure relief valve and glycerin felled pressure gauge.

Ratings:

- 2 – 24 GPM

- 500 – 6000 PSI

- Electric Motor, Gasoline Engine or Diesel Engine

Hot Pressure Washers

Electrically Heated Hot Pressure Washers

Electric hot water pressure washers use electric immersion elements to heat the water with no fumes or exhaust. All-electric cleaning equipment units are great for cleaning in locations that require clean emissions and air quality or hazardous locations where fuel-fired units are not approved for use. Sioux all-electric models require 3 phase electrical power. Sioux manufactures two different lines of all-electric hot pressure washers. The EN Series and E Series. Units meet low NOx requirements because they do not burn any fossil fuels to heat the water.

Sioux’s EN-Series All-Electric Pressure Washers

- Extra heavy-duty industrial design built for use in the most rugged environments.

- The EN-Series includes explosion-proof models, designated by an XP in the model number, for use in hazardous locations.

- Most EN-Series units are combination machines, which means they can be used as either a hot water pressure washer or an industrial steam cleaner.

- Typical applications for these units are in the petroleum and mining industries.

All-Electric E Series

All-Electric E Series

The all-electric Sioux E Series pressure washer is designed for industries that require the same cleaning power as our larger EN Series pressure washers in a more compact and portable design such as

- Pharmaceutical manufacturing

- Chemical manufacturing

- Food and beverage processing

- General manufacturing

Features

- Sioux’s E-Series electric pressure washers all come standard with steam cleaning functionality

- Provide instant and continuous heat without the hassle of preheating storage tanks or a volume of heat transfer fluid.

- Standard features include a NEMA 4 electrical enclosure, stainless steel float tank, long-life heating elements, and adjustable digital temperature control.

- A wide range of options and configurations are available in any voltage in 50 or 60 Hertz.

Oil, Gas & Propane Powered Steam Cleaners

All industrial steam cleaners are not equal in performance. The Dakota II line of gas and oil fired steam cleaners provide up to 320°F (160°C) saturated steam at the nozzle which produces up to 333% more cleaning impact when compared to other brands that only produce 250°F (121°C) saturated steam. Sioux Dakota II industrial propane powered steam cleaners feature an extra heavy-duty industrial steel frame that is built for extremely rugged operating environments such as mining, petroleum, manufacturing, contract cleaning, and the transportation industries. Sioux units are available in a variety of voltages at 60Hz or50 Hz and utilize either an oil (diesel), natural gas, or LP fired burner.

Ratings:

- 1.6 – 8 GPM @ 100 PSI @ 325°F

- 234,000 – 1,125,000 output BTU/Hour

Sioux combination cleaners combine a cold pressure washer, hot pressure washer and steam cleaner all in one unit. A combination cleaner is ideal if several types of cleaning are required. Sioux combination cleaners provide 325-F saturated steam (212-F after discharge from gun nozzle) at 100 PSI on steam cleaning cycle, hot water at 200-F on hot pressure cycle, and cold water on cold pressure cycle. Units come complete with high temperature limit switch, glycerin-filled pressure gauge and pressure relief valve.

Ratings:

- Steam Cycle: 1 – 8 GPM @ 100 PSI

- Pressure Wash Cycle: 2 – 16 GPM C 200°F

- 250 – 2000 PSI

- 145,000 – 1,125,000 output BTU/Hour

All-Electric Cleaners

Sioux All-Electric Units provide similar cleaning power to conventional Sioux units, but are 100% electric. All-Electric cleaners are ideal for applications in which no flame, exhaust or contamination can be tolerated. Sioux’s entire line of All-Electric units are ETL listed, providing third-party certification to UL-1776, and the Canadian Standards Association CSA C-22.2 No. 68-92. All models can be built to explosion-proof specifications. Sioux’s All-Electric equipment meets the U.S. and Canadian National Electric Codes and complies with OSHA Regulation 1910.303(a).

Ratings:

- Steam Cleaners: .6 – 3.8 GPM Q 100 PSI o 325-F Saturated Steam

- Hot Pressure Washers: 1.6 – 5.7 GPM Q 140 or 180-F o 600 – 3000 PSI

- Combination Units: Steam Cycle: .6 – 1.9 GPM C@3 100 PSI o 325-F Saturated Steam Pressure Cycle: 1.6 – 5.7 GPM Q 140 or 180-F 9 600 – 1200 PSI

Safesteam Steam Cleaners – Powerful Steam Cleaning

Safesteam Steam Cleaners – Powerful Steam Cleaning

The SafeSteam™ Model F2.8S150 steam cleaner lets you use your plant’s internal steam as a powerful steam cleaning tool!

If your plant has 80-150 PSI (5.5 -10.3 BAR) steam, here is an innovative way to use that steam for cleaning purposes. The SafeSteam™ is a steam cleaning machine that utilizes your existing in plant steam system, which eliminates the requirements for a burner, and it uses less water, fuel and electricity than a conventional pressure washer or steam cleaner.

Accessories Available to Customize Your Cleaner

The following accessories can be ordered on any Sioux All-Electric cleaner, unless otherwise specified.

| Trailers – For any unit, balance and weft permitting – Factory installation. |

|

| SA-25a | Mini Trailer-2-wheel. Holds up to 1,000 lbs. |

| SA-25b | Trailer-2-wheel. Holds up to 2,000 lbs. |

| SA-26a | Trailer-4-wheel tandem with 15″ wheels. Holds up to 5,000 lbs. |

| SA-26b | Trailer-4-wheel, steerable. Holds up to 10,000 lbs. |

| Water Tanks – For any skid or trailer – mounted unit. Factory Installation. |

|

| SA-27 | Water Tank-Carbon steel. |

| SA-27a | Water Tank-Stainless steel. |

| SA-27b | Water Tank-Polyethylene plastic. |

| Hose and Hose Accessories | |

| SA-32c | Hose-3/8″ x 50′ single wire-braid. For use on steam cycle rated to 60 GPH, and high pressure rated to 2,000 PSI. |

| SA-32f | Hose-3/8″ x 50′ 2-wire braid. For 3,000 PSI high pressure washers, 120-360 GPH. |

| SA-32g | Hose-3/8″ x 25′ single wire-braid. For steam cleaners and combination units, 40-60 GPH. |

| SA-33 | Hose-1/2″ x 25′ single wire-braid. For all steam cleaners, or any combination cleaner 80 GPH or higher. |

| SA-31 | Hose-1/2″ x 50′ single wire-braid. For all steam cleaners, or any combination cleaner 80 GPH or higher. |

| SA-46 | Brass 50- Fan Nozzle. For all steam cleaners and combination units. |

| SA-50b | Quick Coupler-3/8″. For any 3/8″ hose. |

| SA-50c | Quick Coupler-1/2″. For any 1/2″ hose. |

| SA-54a | Hose Reel-Manual crank rewind. |

| SA-54b | Hose Reel-Spring rewind. |

| SA-54c | Hose Reel-Motor-driven rewind. |

| Optional Accessories | |

| SA-76 | Shut-Off Gun-For All-Electric steam cleaners and combination units. |

| SA-43b | Downstream Chemical Injection – Injects chemicals downstream of pump and heating system. Use on hot pressure washers. Factory installation. |

| SA-52a | Alternate Electricals – Electrical voltage and frequency other than listed standards. Consult factory. Factory installation. |

| SA-53 | Time Delay – Delays shutdown of water pump to cool heating element. Factory installation. |

| SA-55 | Sand Grit Injector-Hopper or spade pickup. Use on pressure washers 1,000 PSI and 180 GPH or higher. |

| SA-56 | Wheels-4″ x 16″ with semi-pneumatic tires. Factory installation. |

| SA-56b | Wheels-4″ x 10″ with fully-pneumatic tires. Factory installation. |

| SA-59 | Hour Meter – Records operating time. Electrically operated. Factory installation. |

| SA-69 | Machine Disconnect Switch – Factory installation. |

| SA-70 | Internal Circuit Breakers (in place of standard fuses)-Factory installation. |

Sioux All – Electric Cleaners Designed for Safety, Reliability, Durability

- Third-party certified for safety, meeting UL and CSA standards.

- Ideal for areas where no flame, exhaust or contamination can be tolerated.

- Available in explosion-proof models for use in hazardous areas.

- Hot water is available fast and continuously.

- Heavy-duty construction and quality craftsmanship gives years of trouble-free cleaning.

- Easy to operate and easy to service.

Which is Best… a Hot Water Washer OR a Steam Cleaner?

Myth: Steam cleaners are outdated.

Reality: There are many applications where a steam cleaner may be better than a hot water washer.

At Sioux, we have been building both types of machines for many years. There are some advantages to using hot water washers and some advantages to using steam cleaners. Each cleans in a different way. Determining which machine is best depends on the application.

- With pressure washers, dirt and grime is blasted away, under pressure. Heat will improve the result if melting is required, and use of the proper detergent will enhance cleaning.

- Steam cleaners are best when the substance to be removed turns from a solid to a liquid, or dissolves, with the application of heat. This is the case with grease, oil, tar, many petrochemicals, ice, wax, food products and similar materials. The substance is melted or dissolved, rather than pushed off of the surface. Use of proper detergent will enhance steam cleaning.

With a Dakota™ Series steam cleaner, when heated water at a temperature of 320°F and a pressure of 250 PSI flashes into vapor as it passes through the steam nozzle, there is tremendous expansion, producing about the same impact as a 1,000 PSI pressure washer, with 86% more heat transferred for cleaning.

If heat is what is really needed for cleaning, a steam cleaner is the better choice. In addition, a steam cleaner (vs, a hot water washer) offers the following benefits:

- Operates with less power consumption, reducing your electric bill,

- Requires a smaller electric circuit for installation, and therefore may be used in more locations in your facility,

- Uses less water during operation, reducing your water and sewer bills, and reducing the volume of wastewater to be processed,

- Produces less splattering and splash-back onto the operator and in your facility.

All steam cleaners are not the same. At comparable flow rates, a 320-F steam cleaner produces approximately 40% more steam and will transfer approximately 13% more heat to the surface than the 290-F steam cleaner. The increased heat and steam also significantly increase the cleaning impact, as illustrated in the chart below:

| Pressurized Water Temperature Before Exiting Nozzle as Steam |

% Increase in Cleaning Impact of 320°F vs. Lower Temperatures |

|---|---|

|

320°F vs. 300°F

|

+34%

|

|

320°F vs. 290°F

|

+58%

|

|

320°F vs. 280°F

|

+118%

|

|

320°F vs. 265°F

|

+167%

|

|

320°F vs.250°F

|

+338%

|

What is more important, pressure or flow?

For a given cleaning application there are many flow/pressure combinations from which to choose. Here are some criteria you can use to select the best flow and pressure combination for your application.

- Consider the capacity of your water source. If you have a limited water supply then you should probably choose more pressure than flow.

- Consider how important heat is in your cleaning application. It heat is critical to your cleaning application, then higher flow is better. The more hot water you can move across the surface, the faster you can heat it and clean it. If additional heat would help, a steam cleaner should be considered.

- For a given horsepower there may be several flow and pressure combinations available. Higher flow and lower pressure for a given horsepower will result in more impact and more work. The example below compares two different 7.5 hp machines. You can see that the higher flow rate option results in 29% more work and 40% more cleaning force.

| Example | Rating | % Additional Work |

% Additional Force |

|---|---|---|---|

| High Pressure | 3.5 GPM @ 3000 PSI |

–

|

–

|

| High Flow | 5.3 GPM at 2000 PSI |

29%

|

40%

|

- It is commonly believed that lower flow and higher pressure will produce less runoff, and less wastewater to process. This may be true in some applications. But if a higher flow machine can perform the same job faster, then the total amount of water used may be less. Temperature should also be considered to reduce water consumption. It may be better to use a higher temperature rather than increase flow or pressure in order to minimize your wastewater.

Dakota™ Series Steam Cleaners and Pressure Washers Designed for Safety, Performance, Dependability, and Value

- Third-party certified to UL-1776 and CAN/CSA-B140.11-M89 by ETL

- Meets National Electric Code and Canadian Electric Code

- Gas fired machines meet requirements of American Gas Association and Canadian Gas Association

- Performance Certified to Cleaning Equipment Trade Association Performance Standards

- Designed for easy maintenance and operation

- Efficient coil design lowers fuel usage. Saves you money.

Sioux Trailers for Mobile Cleaning

Any Sioux Cleaner can be mounted on our heavy-duty trailers. All trailers are constructed of 11-gauge rectangular steel tubing and heavy duty angle iron.

Sioux Trailers are ready to use and are available with a variety of accessories. Because most trailers are individually built to the needs of the cleaner, the exact specifications and accessories may vary.

“Over-the-Road” trailers include wiring harness, leveling jack, reflectors, turn signals, break-away safety chains and either ball hitch or lunette eye. If unit has an exhaust hood, rain cover will also be furnished. Self-contained units are available by adding special options such as water tanks, engines, generators and hose reels. Sioux trailers can be customized to meet your requirements.

2-WHEEL TRAILERS

2-Wheel Mini-Trailer

- Capacity: 1,000 lbs.

- Approximate Trailer Weight: 225 lbs

- “Over-the-Road”

SA-25a Mini-Trailer- Features wiring harness, leveling jack, rain cover on exhaust hood, breakaway safety chains, ball hitch, reflectors, turn signals, and easy access to controls. Trailer is complete and ready to use “Over-the-Road.” Leaf spring suspension with 16.5 x 6.5 – 8 tires. Tongue can be removed to decrease required storage space.

| Length (Including Tongue) |

82″

|

| Width |

71″

|

| Height |

24″

|

| Tongue Length |

30″

|

| Trailer Weight, approximate |

225 lbs

|

| Load Capacity |

1,000 IBS

|

2-Wheel Standard Trailer

- Capacity: 2,000 Ibs.

- Approximate Trailer Weight: 350 IBS

- “Over-the-Road”

SA-25b 2-Wheel nailer- Features 15″ 4-ply tubeless radial tires, semi-elliptical leaf springs, complete wiring harness with reflectors for “Over-the-Road” use, easy access to controls, rain cover on exhaust hood, leveling jack; ball hitch and breakaway safety chains, ready to use. Tongue can be removed to decrease required storage space.

| Length (Including Tongue) |

90″

|

| Width |

72″

|

| Height |

33″

|

| Tongue Length |

36″

|

| Trailer Weight, approx |

350 IBS

|

| Load Capacity |

2,000 IBS

|

We are referring to the Siebring Pressure Washer. For those requiring smaller units, lower capacity, economical grade.

All-Electric

All-Electric

Safesteam Steam Cleaners – Powerful Steam Cleaning

Safesteam Steam Cleaners – Powerful Steam Cleaning