WATER STORAGE TANKS AND

WASTE WATER STORAGE TANKS

First to Introduce Powder Coating to the Bolted Tank Industry!

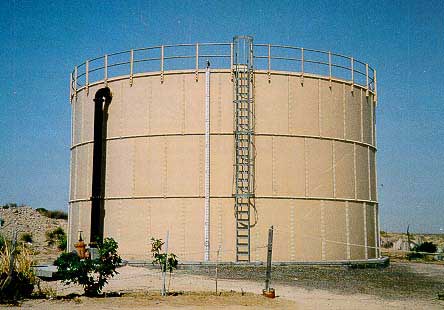

A larger tank installation

| Resistance To: | Characteristics: |

|

|

A Wide Variety of Storage Accessories for Water Tanks

Accessories Available Depending on Your Need

Configurations : One and All

Our tanks are available in standard sizes and configurations ranging from 65 barrels/2,795 gallons all the way up to 24,000 barrels/ I million gallons with larger sizes available on request. Four different styles of tanks standard, cone bottom, vapor tight and open top are available to meet virtually all storage tank needs.

The Standard tank consist of a cone deck and flat bottom. The cone bottom is similar to the standard tank except that the bottom is conical rather than flat. The cone roof of the vapor tight tank is gasketed to insure against loss of vapor. The open top tank features a reinforcing ring around the perimeter of the top stave.

Contact Us Global Resources for all

your Liquid and Dry Tank Storage Product

Installation: Quick and Easy

When you need a Superior Tank, you’ll have it. Within days after you place your order, we’ll be rolling up to prepare the jobsite for construction. And because all our tanks parts are standardized and interchangeable, it means that most jobs go up without a hitch.

What’s more, you can have a Superior Tank just about any way you want it, low and wide, high and narrow, with or without cone bottoms, and with a variety of special appurtenances. They can be erected inside buildings, or on elevated structures. They can be added to for greater capacity, and individual parts and sections are easily replaced.

The precision fabrication of Superior Tanks give you perfectly matched segments for safe dependable storage.

Construction: Tough and Ready

Our bolted steel tanks are designed, engineered and built to take punishment. Decks feature a steel rafter construction and rugged center post support in accordance with API/AWWA standards for even longer life aluminum or fiberglass decks are also available.

Our rubber gaskets are manufactured to exacting specifications to meet virtually any storage need from potable water to crude oil, gasoline and edible oils. Gaskets are accurately pre-punched with bolts slightly smaller than the bolts, preventing leakage along the threads and insuring a tight, leak-proof seal.

All tanks are available with either flush or extended cleanout openings. On the flush design, the cover plate bolts directly to the stave, the extended cleanout fastens a three-inch extension to the stave to which the cover plate is bolted.

Walks and ladders on Superior Bolted Storage Tanks conform to all OSHA requirements.

Coatings : Durability and Chemical Resistance

Superior has adapted the most advanced coating technology available in bolted tank manufacturing. Factory applied ” Thermoset Fusion bonded Powder Coating.”

- Dupont– TANK TAN Interior Epoxy is applied 5 mils thick to interior shell and appurtenances.

- Dupont– SUPERIOR SAND Exterior Polyester (Tan) is applied 3 mils thick to exterior shell components.

Powder Coatings are electrostatically applied and then cured at high temperatures for greater film thickness to achieve adequate bonding and coverage, resulting in added chemical resistance to corrosion, chipping and scratching and other abuses, along with faster turn around time and greater control of thickness and hardness. Our Powder Coatings are NSF 61 approved and they meet all API/AWWA and FDA standards. Superior also features hot-dipped galvanized tanks.

Superior Tanks: Safe and Sound

Meticulous design and engineering, rigidly controlled manufacturing, and careful field erection all contribute to a superior final product and a tank that will do its job with minimal attention for decades to come.

But there’s more to Superior than just our tanks. There’s our service. If any problems arise, you can count on us to be back and make all necessary repairs… FAST. All our tanks come guaranteed.

We stand behind our tanks. So you can turn your back on them.

API 12B Bolted Steel Tank Specifications (bolted steel tank specifications)

Other Bolted Steel Tank Specifications (bolted steel tank specifications)

| Standard Accessories | |

| API 12B | AWWA D 103-97 |

| 24″ x 36″ Dog House Manhole | 24″ Shell Manhole |

| 20″ Shell Washout Window | 20″ Screened Roor Vent |

| 20″ Cone Deck Manhole | 24″ x 24″ Roof Hatch |

| 8″ Gauge Hatch | |

Call us for all your Storage Tank, Wash Tank, and Special Treatment Tank Needs Serving the Potable Water, Fire Protection, Weste Water and Petroleum Industries

Standard Bolted Tank Capacities (U.S. GALLONS)

Standard Bolted Tank Capacities (Cubic Meters-M3)

Storage Tank Performance Evaluations

Why Should you select 3M Scotchkote 134/135 powder coating over glass lined coatings?

- Equal to or Better then the glass lined products at a Lower Cost!!

- Electrostatic application assures 100% adherence and uniformity.

- The Best Chemical Resistance you can get for surface protection.

- Tested in over 1000 common used chemicals.

- High impact and abrasion resistance.

- Easy to repair.

- Environmentally safe.

- Flexible with no cracking.

- Compatible with other coating systems.

- Fast cure, because its never Wet! (Max. 25 minutes)

- Scotchkote 134/135 coating has been tested and certified to ANSI / NSF-61 standards.

- And all the support and experience of a world wide company !!! 3M™ products.